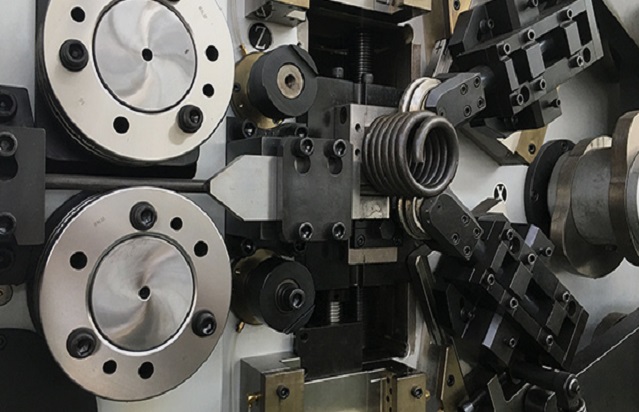

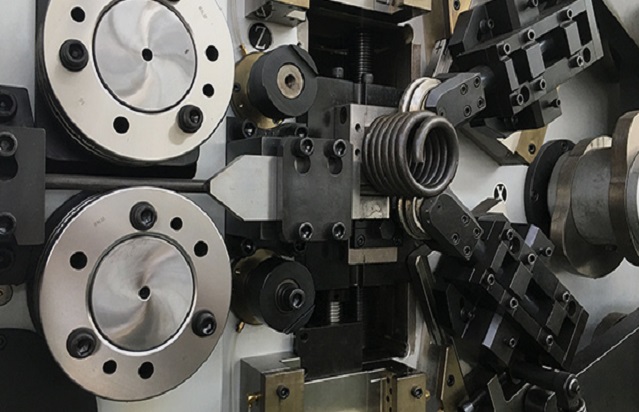

Due to the limitation of the product structure of the spring factory, the multi-strand spring usually has the characteristics of high strength and good performance. The spring factory tells you the material properties to ensure the strength and toughness of the spring.

Springs produced by spring manufacturers should pay attention to the following during processing:

1. The support right can choose hot and cold methods according to product requirements. The hot method does not allow the spring to heat up, spark or turn white, and the temperature of the silicon-manganese steel cannot exceed 850. The supporting ring and the effective ring are in effective contact, and the distance between them should not exceed 10% of the nominal distance between two turns.

2. The characteristics of the multi-strand spring can be determined by adjusting the track, and the cable distance can be adjusted when winding. The lay length can be 3 to 14 times the diameter of the steel wire, but it is generally recommended to take 8 to 13 times. In addition, the spring force is closely related to the free height, parallel coil, outer diameter and wire properties, and can be changed by adjusting one or more of them.

3. Springs without a support source and springs with too thin steel wire diameters cannot be welded to the spring head, but the end steel wires cannot be obviously loosened and deburred. The length of the welded part of the multi-strand spring head that needs to be welded should not exceed 3 times. The heating length should be less than one circle, and it should be smooth after welding. When gas welding, the welding part should be annealed at low temperature.

4. Spring factory home: Generally, the surface treatment of springs only needs phosphating treatment, and other treatments are also available. When electroplating zinc and cadmium, dehydrogenation after electroplating. After dehydrogenation, test 3% (within 3 times), and test again, and the retest cannot be interrupted. Springs need to be cleaned of surface dirt, salt marks and scale. This method can clean sand or gasoline, but cannot use acid washing.

5. Spring factory home: The spring compression time is 24 hours, and generally the spring is maintained for 6 hours or continuously compressed 3~5 times, each time for 3~5 seconds. When it is tight, the distance between the spring and the mandrel is preferably 10% of the mandrel diameter. If the spacing is too small, it will be difficult to operate. If the distance is too large, the spring is easy to bend. When it's tight, if one spring fails, the rest have to be reworked.

6. For multi-strand springs with a large H0/D2 value, attention should be paid to the deformation during heat treatment, whether the mandrel is worn, the placement method, and the selection of appropriate heat treatment equipment. Experts from the spring factory suggest that under the condition of recyclability, multiple tempering and hot pressing can be carried out to achieve the purpose.

Most of the spring materials produced by our company have different degrees of elasticity. After bending, the prototype can be restored with great force.

If you want to know more about the spring machine, please consult

Zhejiang Omnipotent Spring Machine Co.,ltd. for details!