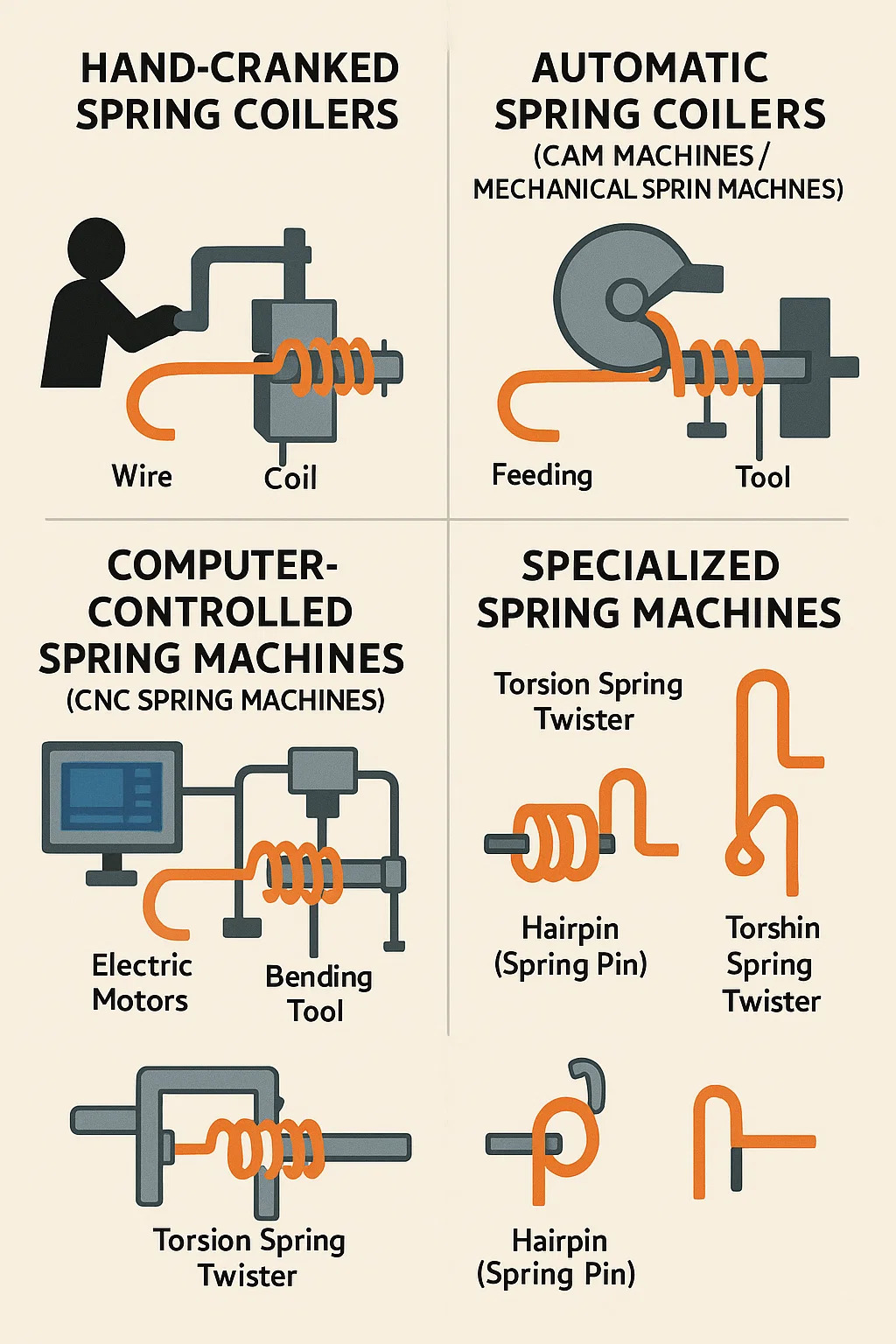

Here's a breakdown of machines used to make springs, in plain language:

Content

All spring-making machines take a long, straight piece of metal wire and bend it repeatedly into the right coiled or shaped form, then cut it to length. The key difference is how they control those bending steps.

•How they work: Think of these like simple tools. An operator turns a handle by hand.

•The handle turns gears or levers: This movement pushes the wire against fixed pins or shaped blocks ("formers") that bend it around a central rod ("mandrel").

•Operator does everything: The person controls the speed, how much wire is fed for each bend or coil, and when to cut the finished spring (often with separate cutters).

•Good for: Making small batches, simple springs, repairs, or when just starting out. They're slower and require more skill to get consistent results.

•How they work: These are the classic factory workhorses. They run automatically once set up.

•Cams are the "brain": Inside the machine, specially shaped metal wheels (cams) rotate. As they turn, their shape pushes rods or levers.

•Levers move the tools: Those levers control the bending fingers, wire feeding mechanism, and cutting blade. Each cam's shape dictates when and how far a tool moves.

•Setup is key: A skilled worker spends time installing the right cams, adjusting the bending fingers precisely, and setting the feed length. •Once set, the machine can churn out identical springs very fast.

•Good for: Making large quantities of the same spring design very efficiently. Changing to a different spring design requires changing cams and retooling, which takes time.

•How they work: These are the modern, flexible machines. They have a computer screen and controls.

•Computer gives instructions: Instead of cams, the machine follows step-by-step instructions programmed into its computer. You tell it the wire size, coil size, number of coils, bend angles, etc.

•Electric motors do the moving: Separate, precise electric motors drive the wire feeder, each individual bending finger, and the cutter. The computer tells each motor exactly when and how much to move.

•Quick changeovers: Switching to a different spring design is mostly done on the computer – load the new instructions. Physical tool changes are quicker too.

•Good for: Making complex spring shapes, small batches of many different designs, prototypes, and springs that need very high precision. They're versatile but usually cost more.

•Torsion Spring Twisters: Focus on twisting the wire ends precisely for springs that work by twisting (like clothespin springs).

•Hairpin (Spring Pin) Machines: Make small, straight springs with bent ends, often used in locks or clutches.

•Heavy-Duty Coilers: Built to handle very thick wire for large industrial springs.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details