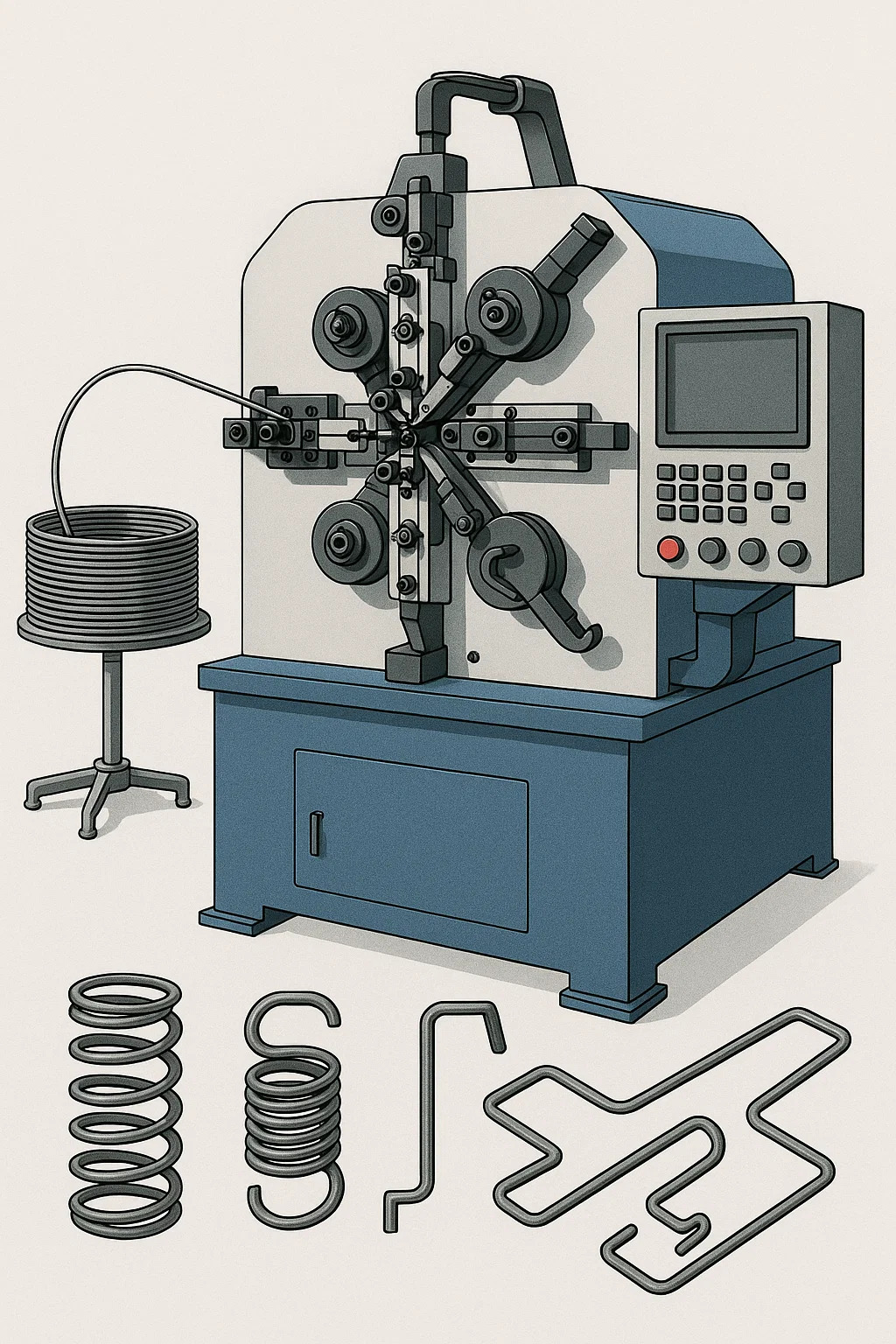

Spring machines are specialized industrial equipment designed for high-volume manufacturing of precision metal components. Their primary functions include:

Content

Compression Springs: Creating helical springs that resist pushing forces (e.g., car suspension, pens, mattresses).

Tension Springs: Making helical springs with hooks or loops designed to resist pulling forces (e.g., garage doors, trampolines, balance scales).

Torsion Springs: Producing springs that exert rotational force or torque when twisted (e.g., clothespins, mouse traps, door hinges).

Wire Forms & Special Springs: Fabricating complex geometries like wave springs, constant force springs, clip springs, and intricate shaped springs needed in electronics or medical devices.

Beyond standard springs, these machines shape wire into diverse 2D and 3D components used across industries. Examples include:

Automotive: Clips, brackets, retainers, seat frame parts.

Electronics: Connector pins, shielding contacts, antenna elements.

Consumer Goods: Hangers, hooks, handles, basket frames, toys.

Medical: Surgical instrument parts, implant components, orthodontic archwires.

Industrial: Retaining rings, cotter pins, safety pins, chain links.

Performing multiple, highly accurate bending operations on wire in a single setup.

Creating consistent angles, radii, loops, coils, and complex curves repeatedly.

Feeding straight wire continuously from a coil.

Precisely cutting wire to exact lengths during or after forming.

Optionally incorporating secondary operations like end flattening, threading, tapping, or surface treatments within the cycle (more common on advanced CNC machines).

Enabling rapid, automated production of thousands of identical parts per hour with minimal operator intervention once set up.

Ensuring consistent part dimensions and tolerances critical for assembly and function.

Efficiently transforming coiled metal wire (steel, stainless steel, copper alloys, titanium, etc.) into finished or near-finished components, minimizing waste.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details