Power system circuit breaker operating mechanism is divided into spring mechanism, hydraulic mechanism, pneumatic mechanism and hydraulic disc spring mechanism. Next,

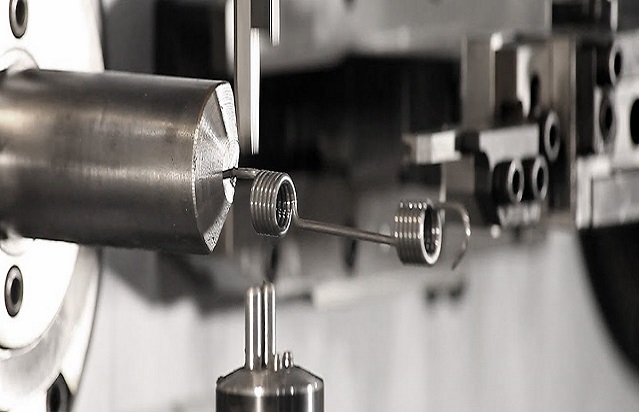

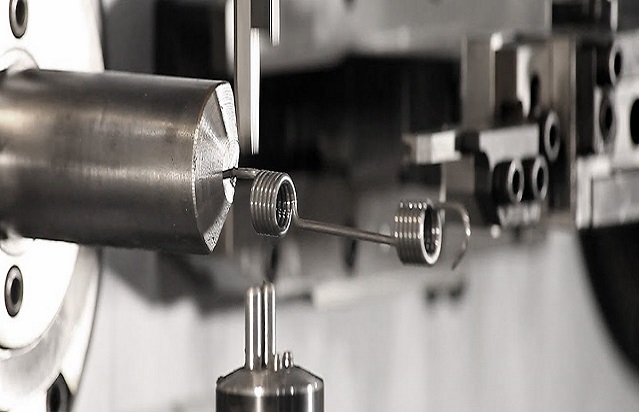

Zhejiang Omnipotent Spring Machine Co., Ltd. will introduce the working principle of the spring operating mechanism.

1. Principle The spring operating mechanism is a mechanical operating mechanism with a spring as an energy storage element. The energy storage of the spring is completed by the motor through the deceleration device, and is kept in the energy storage state through the locking system. When breaking, the latch is released by the magnetic force, the spring releases energy, and the contacts move through the mechanical transmission unit.

2. The spring operating mechanism has simple structure and high reliability, and the opening and closing operation is realized by two helical compression springs. The motor stores energy for the closing spring. When closing, part of the energy of the closing spring is used for closing, and the other part of the energy is used for energy storage of the opening spring. As soon as the closing spring is released, the energy storage motor will store energy immediately, and the energy storage time does not exceed 15s (the energy storage motor is an AC/DC dual-purpose motor). During operation, the time-sharing closing spring is in a compressed state, while the release of the opening spring has an independent system, which has nothing to do with the closing spring. The spring operating mechanism designed in this way has high reliability and stability.

Opening operation: The opening signal energizes the opening coil and makes the opening striker strike the opening trigger, the trigger rotates clockwise and releases the opening holder, which also rotates clockwise to release the shaft on the main crank arm pin. The opening spring force makes the main crank arm rotate counterclockwise, and the circuit breaker is disconnected.

When the switch is in the opening position, the closing spring is in the energy storage state (the opening spring has been released), and the cam is connected with the ratchet through the camshaft. The ratchet has a clockwise moment under the stored closing spring force, but is locked by the closing trigger and closing spring charged latch, and the switch is held in the off position.

Closing operation: The closing signal charges the closing coil, causing the closing plunger to hit the closing trigger. The closing trigger rotates clockwise to release the closing spring energy storage clip, and the closing spring energy storage clip rotates counterclockwise to release the pivot pin on the ratchet. The closing spring force makes the ratchet drive the camshaft to rotate counterclockwise, the main crank arm rotates clockwise, and the circuit breaker completes closing. At the same time, the opening spring is compressed to store energy. When the primary crank arm is turned to the end of its stroke, opening the trigger and closing the holding latch locks the pivot pin and holds the switch in the closed position.

When the switch is in the closed position, the close spring is released (the open spring has stored energy). After the circuit breaker is closed, the cam plate connected to the ratchet closes the limit switch, the electromagnetic switch is energized, the motor circuit is connected to start the energy storage motor, and the energy storage motor is transmitted to the eccentric wheel connected to the pair of pawls through a pair of bevel gears. The rotation of the eccentric wheel makes the pair of pawls step on the ratchet alternately, so that the ratchet rotates counterclockwise and drives the closing spring to store energy. With the closed spring charged in place, the latch is kept locked by the closed spring charged. At the same time, the cam plate causes the limit switch to cut off the motor circuit. The closing spring energy storage process is completed.