■Core Definition:

A spring machine is a type of industrial machinery specifically used to produce springs of various shapes and specifications from metal wire (such as steel, stainless steel, or copper wire) through processes such as bending, winding, and forming.

Its core function is to efficiently, accurately, and repeatedly process straight wire into spiral or other complex metal parts with specific elastic properties. Its primary product is various springs.

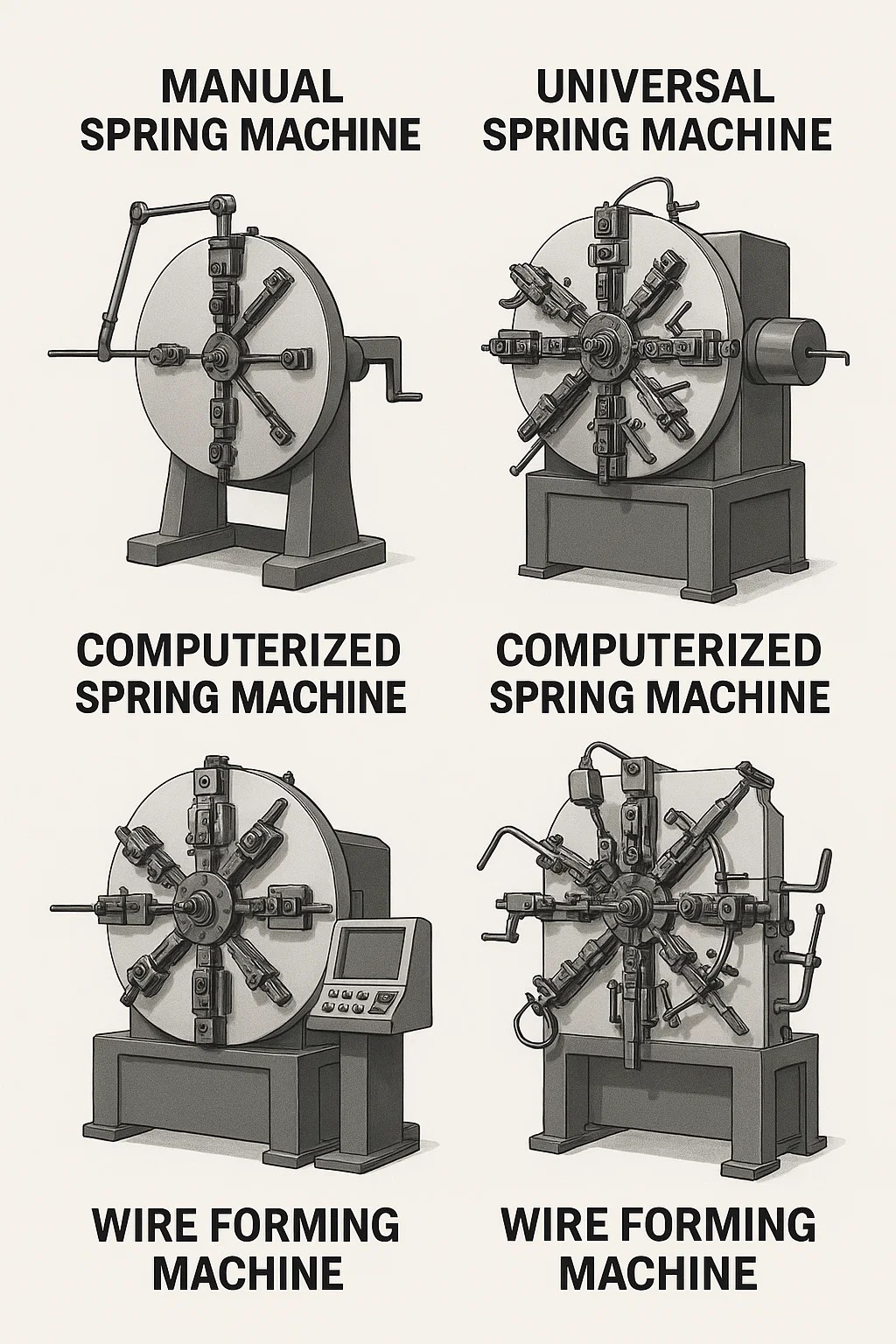

■Main Types (by Operating Principle and Level of Automation):

--Manual Spring Machine:

The most basic model relies on a hand crank or lever to provide power.

Basic parameters such as the spring's outer diameter and number of coils can be adjusted by changing different "cams," "gears," or "dies."

This machine has a simple structure and low price, but it also has low production efficiency and poor precision consistency. It relies on worker skill and is suitable for small batches or simple spring production.

--Universal Spring Machine (Cam Spring Machine / Mechanical Spring Machine):

The most common type of industrial spring machine. The core power source is an electric motor, which, through a complex mechanical cam transmission system, precisely controls the movement sequence and amplitude of each "forming knife" (also known as a "wire gauge," "wire feed wheel," "pitch knife," and "cutting knife," among others).

Before production, an experienced craftsman manually adjusts the cam angle, replaces gears, and precisely sets the position and stroke of each knife according to the spring drawing. This process is called "machine tuning."

Once the machine is tuned, it can stably and efficiently mass-produce the same spring type, with precision and consistency far exceeding that of manual spring machines. It is suitable for medium-volume production of springs of moderate complexity.

--Computerized Spring Machine (CNC Spring Machine):

Currently the most advanced and mainstream type of spring machine.

The core is a computer numerical control system. The operator enters detailed spring parameters (wire diameter, outer diameter, number of coils, pitch, end shape, etc.) through programming software (usually using a graphical interface), which generates a machining program.

Servo motors within the machine directly drive the independent movement of each forming knife (wire feeding, coiling, pitch control, cutting, etc.), completely replacing the complex mechanical cam structure. Significant Advantages:

Extremely Fast Changeover: Changing products requires only a new program, requiring little or no manual adjustments (such as changing cutters), significantly reducing setup time.

High Precision: Servo control ensures repeatable positioning accuracy for every movement.

Extreme Flexibility: Easily produces springs with extremely complex shapes, multi-angle bends, special hooks, and even complex wire forms (see next point).

Stable and Efficient Production: Suitable for automated production of a wide variety of products, small batches, and large quantities.

--Wire Forming Machine:

This can be considered a more powerful and flexible extension of the computerized spring machine.

It also utilizes a multi-axis servo motor CNC system.

The key difference lies in its increased number of forming stations (typically 8, 10, or even more) and more flexible tool configurations.

It can produce not only springs, but also a variety of complex three-dimensional metal wire bent parts, such as clamps, hooks, brackets, special-shaped springs, car seat frames, shopping cart baskets, and more. Its "forming tool" functions are more diverse, including bending, flattening, stamping, welding (and sometimes integration). Essentially an extension of the spring machine's functionality, it's used in a wider range of precision wire forming applications.

■Key Components:

Payoff: Holds the wire reel and provides stable wire feeding, typically with tension control.

Straightening Mechanism: Straightens the coiled wire before entering the forming area to ensure forming accuracy.

Wire Feeding Mechanism: Driven by a servo motor (computer) or mechanical cam (universal machine), the rollers precisely advance the wire to the set length. This is crucial for consistent spring length.

Forming Mechanism: The core area. It consists of multiple "forming knives" (curling knives, pitch knives, cutting knives, bending knives, etc.) that can move independently or in conjunction. These knives move according to a program or cam-set trajectory, working together to bend, coil, and cut the wire into the desired shape.

Control System:

Universal Machine: Mechanical cam box, adjustment handle, gear train.

Computer/Wire Forming Machine: Industrial computer (CNC controller), operation panel (display), servo drive. Auxiliary Equipment (Optional): Such as automatic oilers (for lubricating wire), heating devices (for hot-coiling large springs), automatic material receiving trays, and online inspection equipment.

■Core Processing Capabilities:

Coiling: Coiling wire into various helical spring shapes, including cylindrical, conical, convex, and concave shapes.

Bending: Forming hooks, loops, arms, and other shapes at various angles at the ends or center of the spring.

Pitch Control: Precisely controlling the distance (pitch) between adjacent turns of the helical spring, which can be either uniform or variable.

Cutting: Precisely cutting the wire after the spring is formed.

Flattening/Punching: Flattening the ends or specific areas of the spring into shape (commonly used in wire forming machines).

Creating Complex Wire Formed Parts: Through multi-station, multi-step continuous bending (a specialty of wire forming machines).

■Applications:

Spring Manufacturing: This is the most basic and widespread application, used to produce various compression springs, extension springs, torsion springs, wave springs, and special-shaped springs. Precision Wire Forming: This machine manufactures a variety of metal wire parts requiring high-precision bending and forming. It is widely used in nearly every industrial sector, including automotive, electronics, medical devices, furniture, hardware tools, and consumer goods.

■ Selection Factors:

Product Requirements: Complexity, precision requirements, and dimensional range (wire diameter, outer diameter, and length) of the spring/wire component.

Product Scale: Small batches with multiple varieties (suitable for computer machines), large batches with a single variety (suitable for both universal and computer machines), and extremely complex parts (wire forming machines).

Cost: Equipment investment (manual machines > universal machines > computer machines > wire forming machines), machine setup/programming costs, and production efficiency costs.

Operational Requirements: Machine setup difficulty (universal machines rely on the experience of the machine operator, while computer machines are relatively intuitive to program) and ease of operation.

■Safety and Operation:

Spring machines are power machines with many moving parts and high forces. Safety procedures must be strictly adhered to during operation (e.g., wearing protective glasses, avoiding loose clothing, and operating near moving parts without gloves).

Operators require training to understand the machine's principles, operating procedures, and potential risks. Universal machine operators in particular need extensive experience in mechanical adjustment, while computer machine operators need to master the basics of programming.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details