Content

A used spring coil machine is a "seasoned veteran" that has been used by a previous owner and is now back on the market.

Although it's second-hand, its essence remains unchanged: it's still a powerful tool specifically designed to coil straight metal wire into spiral springs. Many factories choose this highly cost-effective equipment to save costs because of its robust structure; with proper maintenance, it still performs efficiently and reliably.

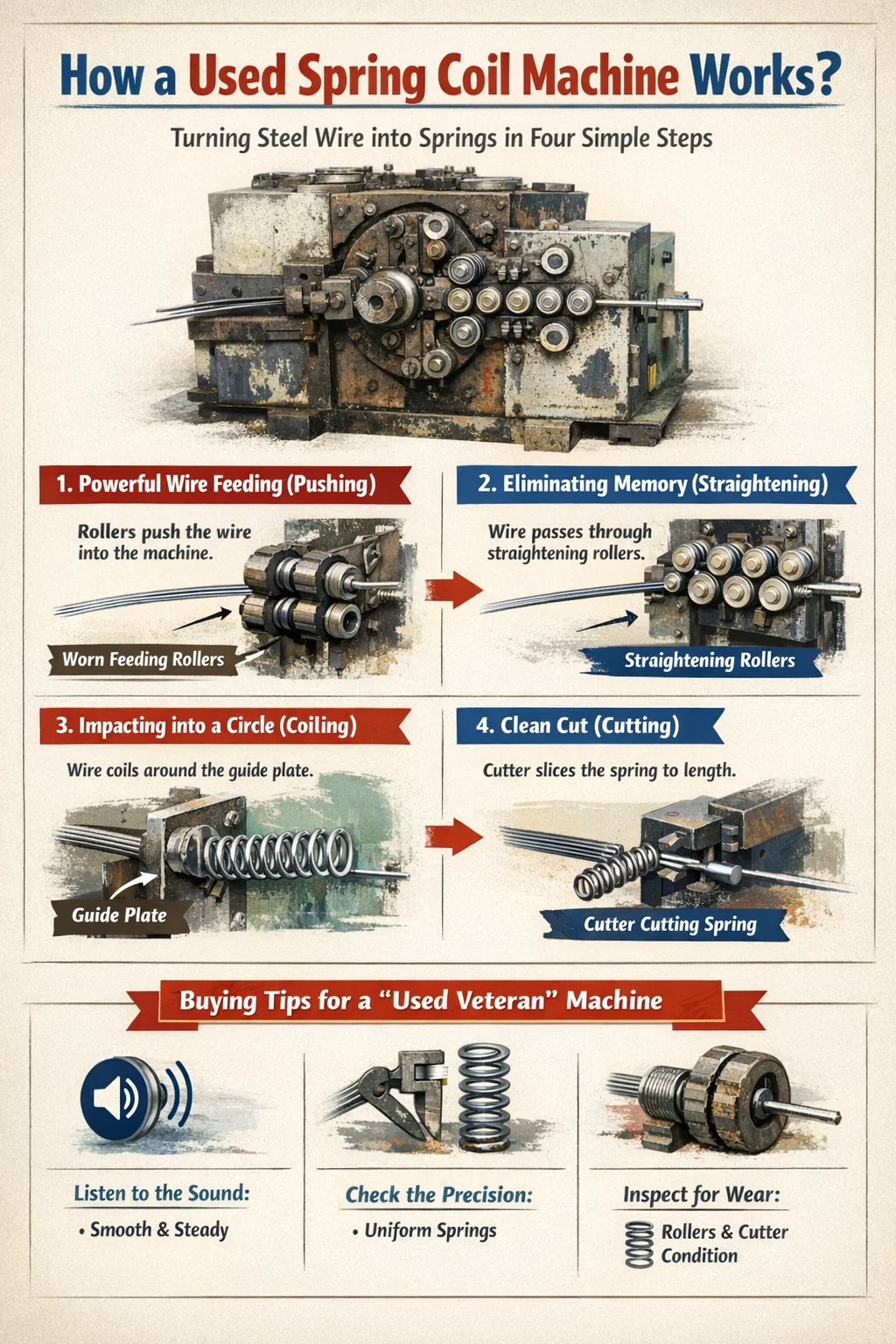

Whether it's a new machine or a used spring coil machine, the core logic of transforming steel wire into springs is the same, mainly relying on these four steps: "pushing, straightening, impacting, and cutting":

At the back of the machine are several rollers that tightly grip the steel wire. They act like a pair of strong hands, continuously pushing bundles of steel wire into the machine. For used spring coil machines, the wear and tear of these rollers is a major concern, as the stability of the wire feeding directly affects the accuracy of the springs.

Due to being wound on a spool for a long time, the steel wire has a "bending memory." Before the coiling process, it passes through several sets of interlocking small rollers. After being squeezed through these rollers, the wire becomes straight, like being ironed flat, ensuring that the resulting springs don't jump around.

This is the most crucial step. After the straightened steel wire is pushed out, it hits a very hard metal stopper (guide plate).

Because it's being pushed from behind and blocked from the front, the steel wire has "nowhere to go" and can only bend along the curve of the stopper.

As the steel wire is continuously pushed in, it naturally coils into one circle after another.

While coiling, a small push rod (pitch knife) in the machine gently pushes from the side. This push creates a gap between the coils of the spring. A stronger push results in a larger gap; without the push, the result is a tightly wound tension spring. Clean Cut (Cutting): When the spring has been wound to the predetermined number of turns or length, the cutter above the machine quickly descends, and with a "click," the wire is cut. A brand new spring then drops from this used spring coil machine.

Listen to the sound: If the old machine runs smoothly with a consistent rhythm and no jarring noises, it indicates that the internal gears and bearings are still in good condition.

Check the precision: Make one hundred springs continuously and see if their length and thickness are exactly the same. This best reflects the condition of the used spring coil machine.

Check for wear and tear: Pay close attention to the wire feeding wheel and the cutter. These are the parts that experience the most stress during operation. If the wear is too severe, you may need to replace parts after purchasing it.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details