Content

Simply put, a torsion spring machine is a machine specifically designed to make "torsion springs."

If you've ever seen a wooden clothespin or the pivot of an automatic door, the spring inside with a coiled center and two "legs" extending from each end is its creation. Ordinary spring machines might only coil simple circles, but a torsion spring machine can not only coil the wire but also bend the ends of the spring into various complex angles, allowing it to hook onto or support other parts.

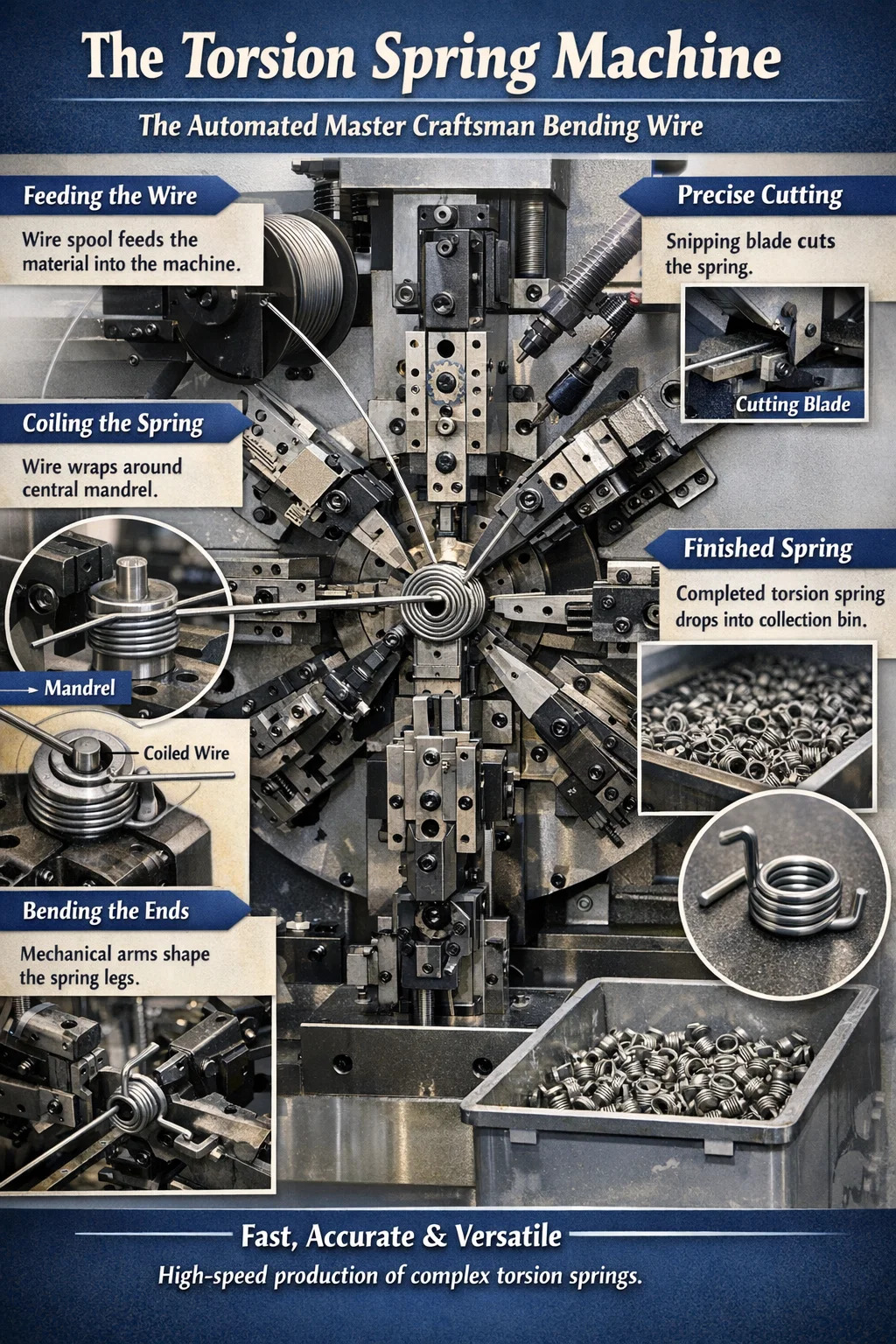

We can think of its working process as an "automated master craftsman bending wire":

▪ Continuously "feeding" the material: A large spool of wire is mounted at the back of the machine. The spring machine's wire feeding mechanism, like a human hand, tightly grips the wire and precisely pushes it into the mold at the front. A computer controls how much wire is pushed and how fast, ensuring that each spring uses the same length of material.

▪ "Coiling" around a central point: When the wire is pushed to the center of the machine, it hits a fixed mandrel. As the wire is continuously pushed forward, it is forced to bend along a circular track, coiling around and around. This is the "body" of the torsion spring that stores energy.

▪ "Bending the legs" and "shaping" the spring: This is the most impressive part of the torsion spring machine. During or after the coiling process, several "mechanical arms" (i.e., sliders or rotating heads) distributed around the machine extend like fingers from different angles, forcibly bending the ends of the wire.

Some are bent at right angles.

Some are bent into small hooks.

Some are twisted repeatedly to create complex spatial shapes.

▪ A clean and precise "snip": Once the coil is formed and the legs are bent to the predetermined shape, the cutting blade inside the machine quickly pops out. It finds the correct position and precisely cuts the wire. A complete torsion spring is born and drops directly into the collection basket below.

▪ Numerous movements: Because it's responsible for bending those "long legs," this type of spring machine has far more movements than ordinary machines, capable of bending the wire from above, below, left, right, and even diagonally.

▪ Fast response: Modern torsion spring machines are computer-controlled. Once the program is set, it can produce a spring in just a few seconds, and each one is identical, ensuring high precision.

▪ High flexibility: If you want to make a different type of spring, you don't need to disassemble and reassemble the machine. Simply adjust the parameters in the computer and change a few molds, and it can immediately start producing a different shape of torsion spring.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details