Content

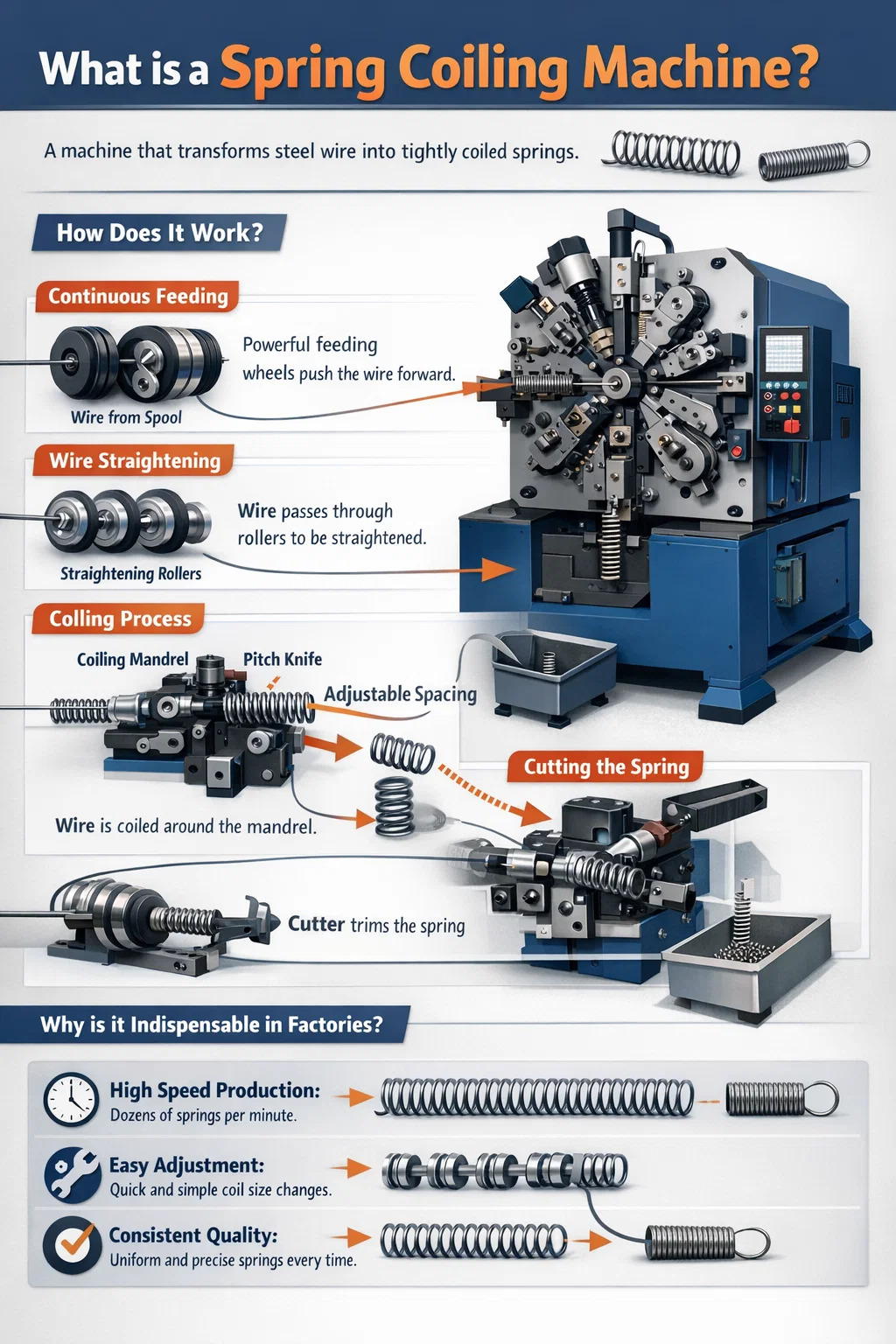

Simply put, a spring coiling machine is a machine specifically designed to "coil" metal wire into a spiral shape.

If you've ever seen the compression springs in a ballpoint pen, or those long tension springs, they are mostly made by this type of machine. Its core task is to transform a straight piece of steel wire into a series of coils, like a spiral slide. Compared to more complex, multi-functional machines, the spring coiling machine focuses on the core skill of "coiling," making it highly efficient.

To transform a metal wire into a neat spring, the machine internally performs a precise coordination of "pushing and blocking":

The back of the machine has powerful feeding wheels. They tightly grip the steel wire and push it forward at a constant speed, like a conveyor belt. The amount of wire fed directly determines the final length of the spring.

The steel wire is usually bent and crooked when it comes off the spool. Before entering the coiling area, it passes through several sets of offset wheels. The wire is straightened as it passes through these wheels, which is essential for ensuring the spring is not crooked.

When the straight steel wire is pushed out, it hits a very hard block (usually called a coiling finger or mandrel).

With the wire being pushed from behind and blocked from the front, it is forced to bend along the curve of the block.

As the wire is continuously pushed out, it naturally forms a continuous circle. Adjusting the position of this block changes the size of the spring coils.

If it were only coiling, the result would be a tightly wound metal tube. To allow the spring to compress, the machine also has a special "push rod" (pitch knife). During the coiling process, it applies a lateral force to the wire, creating a certain distance between the coils.

When the spring is coiled to the predetermined length, the cutter on top of the machine quickly descends like a pair of scissors, cleanly cutting the wire. A complete helical spring is thus created and drops down.

Very fast speed: A specialized spring coiling machine operates like a machine gun, producing dozens or even hundreds of springs per minute.

Easy adjustment: By adjusting a few knobs or program parameters on the machine, the thickness, length, and spacing between coils of the spring can be easily changed.

Consistent quality: Compared to manual winding, the springs produced by the machine have almost identical diameter and tension for each coil, making them ideal for mass production.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details