The compression spring machine can be loved or applied by everyone. It must be because of its advantages. Because of its advantages at all levels, it is all relatively good. Let me inform everyone below.

Metal wires can be produced and processed into different products according to the compression spring machine, such as springs, artworks, and uniquely shaped products. The expansion of market demand has clearly put forward a large number of regulations on the appearance and type of products. Traditional Camshaft compression spring machines (that is, eight-jaw machines, or all-round machines) have long been unable to meet the requirements of customers. Therefore, in the basic development trend of camshaft compression spring machines, camshaft compression spring machines have been developed.

What is the difference between the two? Camshaft compression spring machine, with 8 engine camshafts on the control panel during work, and the 8 engine camshafts are driven by an AC servo motor. Then the camshaft of the engine camshaft driver rotates, and the camshaft then pushes the working guide rail to slide. Block movement. Because the 8 engine camshafts are separately moving, it is necessary to arrange the camshafts according to the product, so that the guide rail sliders in each work will perform the posture. Although it is not easy to create another posture on the steel wire, the whole process of work All the camshafts in the machine are always rotating. If the adjustment staff is negligent and the camshafts are not arranged, there will be a chance of knife collision.

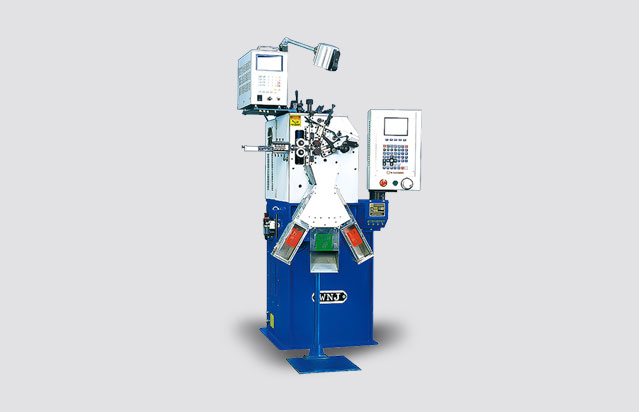

The eight engine camshafts on the camshaft-free compression spring machine are all controlled by separate AC servo motors, so they can independently control the movement of each engine camshaft. The engine camshaft immediately drives the guide rail slider, and the master is adjusting the whole In the process, the angle of view of the camshaft is not arranged, only the computer system and the relative programming can be understood, thus greatly reducing the difficulty coefficient in the whole process of adjustment. Moreover, because it is operated independently, the 8 engine camshafts do not need to be moved separately, which also greatly reduces the power engineering cost. At the functional level, the camshaftless compression spring machine can consider the production and manufacture of more complicated metal material laser cutting processing.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details