Content

Simply put, a spring making machine is a specialized piece of equipment that takes coils of straight metal wire and, through powerful bending, winding, and precise cutting, transforms them into the springs we see everywhere in our daily lives.

Whether it's the large springs in mattresses or the small springs in lighters and ballpoint pens, they are all mass-produced by this type of machine.

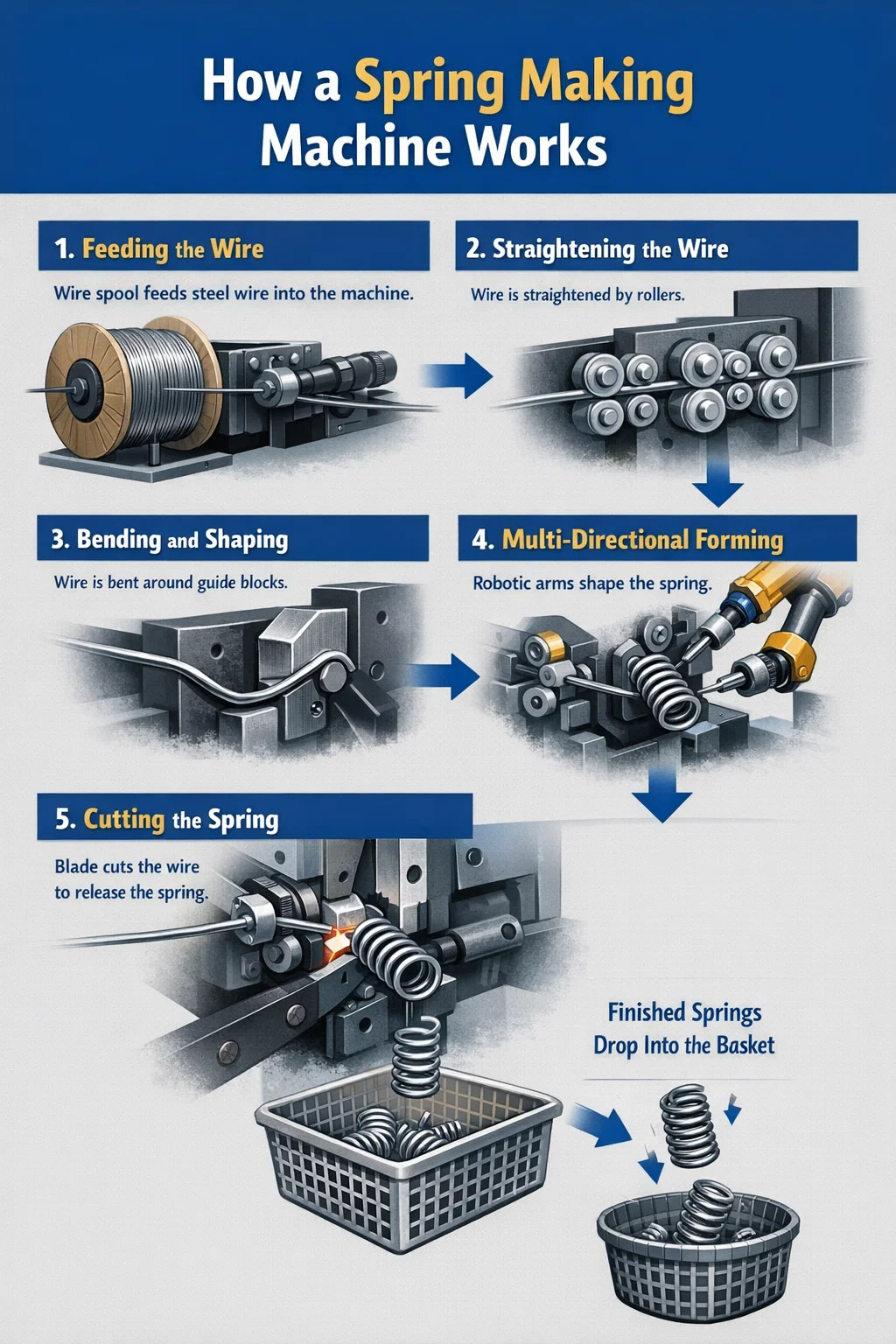

We can break down the working process of a spring making machine into several steps:

At the back of the machine is a large rack holding hundreds or thousands of meters of steel wire. Inside the machine, a set of rotating rollers tightly grip the wire, continuously feeding it into the core of the machine. The amount and speed of the wire fed directly determine the length of the spring.

The steel wire is bent when it comes off the spool, so the first step inside the machine is to pass it through a series of strategically placed small wheels. The wire is squeezed between these wheels, like being ironed, becoming straight and flat, ensuring that the resulting spring is not crooked.

This is the most crucial step. When the steel wire is pushed out, it hits a very hard metal block or pin (usually called a guide plate or curve guide).

Because the wire is being pushed forward by the rollers behind it, and there's something blocking it in front, it can only bend along the shape of the block.

A shallower angle of the block results in a larger spring coil; a steeper angle results in a tighter spring coil.

Modern spring making machines usually have several movable robotic arms. If springs with hooks or unusual shapes are required, these robotic arms extend from various directions—up, down, left, and right—bending the wire into the predetermined shape, much like bending a wire by hand.

When a spring has been wound to the required number of turns or length, the cutting blade in the machine quickly pops out. It precisely locates the position and cuts the steel wire. A complete spring is then made and drops directly into the basket below.

Extremely fast: Manually bending a spring might take several minutes, but this professional spring-making machine can produce several springs per second.

Identical in appearance: It is controlled by a computer or precise gears, ensuring that thousands of springs produced are virtually identical in size and elasticity.

No more hand fatigue: Steel wire is very hard and difficult to bend manually, but the machine has great power and can handle even very thick wires with ease.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details