In recent years, with the development trend of the spring machine industry, the total number and types of spring machine springs, especially special-shaped cross-section wire spring machine springs, have gradually expanded. Special-shaped spring machine springs have the characteristics of large bending stiffness, long life, and small size. But the development trend of its design concept is relatively slow. At this stage, in addition to the more complete design methods for super-strong springs with square cross-sections, the design methods for other super-strong springs with cross-sections are based on actual cross-sections. The characteristics of similar springs and the difficult design solutions are introduced.

This problem is a difficult problem that those who apply this kind of spring are very concerned about and must figure out. The following is a comparison between a square section and a circular section helical spring.

In the same indoor space, the bearing capacity of the square section wire spring is 43-48% higher than that of the round section spring. It goes without saying that the rectangular frame spring should exceed 50%.

Excessive applied ground stress is the key root cause of spring damage. Under the same standard, the service life of special-shaped section wire springs is 13-14% longer than that of round section wire springs.

Special-shaped cross-section wire springs can cause large deformations.

The net weight of the special-shaped wire spring.

The linearity is better than that of the round section spring, that is, the bending stiffness tends to the normal value. It is a spring with the long side parallel to the centerline coil inductance.

The scope of application is subject to certain restrictions: from the analysis, it can be seen that if the advantages of the special-shaped cross-section raw material spring cannot be fully used, it is not easy to cause economic benefits. What is the best application?

(1) The design plan load cannot be achieved by using circular cross-section materials.

(2) Replace the circular cross-section compound spring.

(3) In the case where the necessary deformation cannot be achieved with the round material spring.

(4) Spring installation in areas with small indoor space.

(5) Areas with strict spring characteristics.

Spring design principle of spring machine

1. The selection of the shear strength [τ] of the spring material should be taken into consideration to ensure the fatigue life of the spring.

The dynamic service life of spring machines is generally divided into three categories:

Class I: The frequency of bearing alternating load is 106;

Class Ⅱ: The frequency of bearing alternating load is 103-105;

Class III: The frequency of bearing alternating load is less than 103;

2. The raw material goodness ratio (a/b) is not suitable to be too large, and the winding of the spring is not suitable to be too small.

3. When designing a special-shaped spring with a non-rectangular frame, it is necessary to calculate and plot the curve or calculation method of different rotation ratio, different thickness ratio, deformation correction coefficient (τ) and shear stress correction coefficient (β).

4. It is necessary to select effective design methods based on the given standards and limiting standards, simple calculations and main parameters.

There are still problems

1. The standardization level of stamping spring machines is low, which limits the development trend rate of standardized spring machines.

2. The spring standardization level of spring machine is low. At this stage, except for the QC7111-7113 specification formulated by the automobile industry, there are no national standards or national standards announced in China. The staff of the stamping spring machine has no standard to choose from, which is an urgent problem that needs to be addressed. .

3. The design outline is not perfect. At this stage, the rectangular frame cross-section spiral spring is more perfect, but there is no conclusion on the use of its dimensional tolerance. The spiral springs with special-shaped cross-sections are all based on rectangular frame cross-sections, which have been adjusted in many ways through experiments.

4. There is no designated factory for the production of special-shaped cross-section raw materials, and there is no manufacturer of oil heat-treated quenched steel wire with such raw materials. However, the quality of raw materials reformed by the spring manufacturer itself is unstable and the engineering cost is high, which endangers the application and promotion of this type of spring.

5. There is no special coil spring machinery and equipment for manufacturing such springs. The spiral spring winding ratio for spring machines is generally lower than 4, while the Chinese compression spring machine can use coil inductance winding ratios above 4.

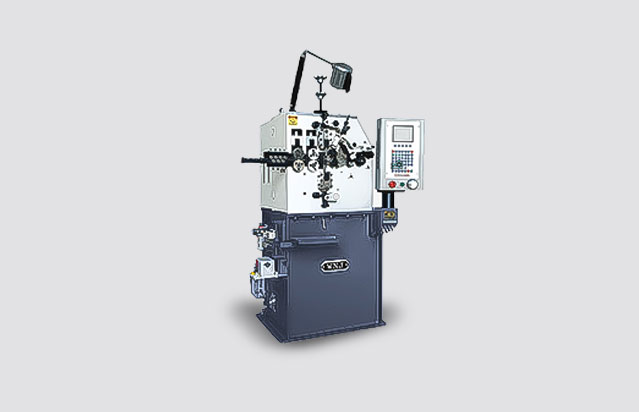

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details