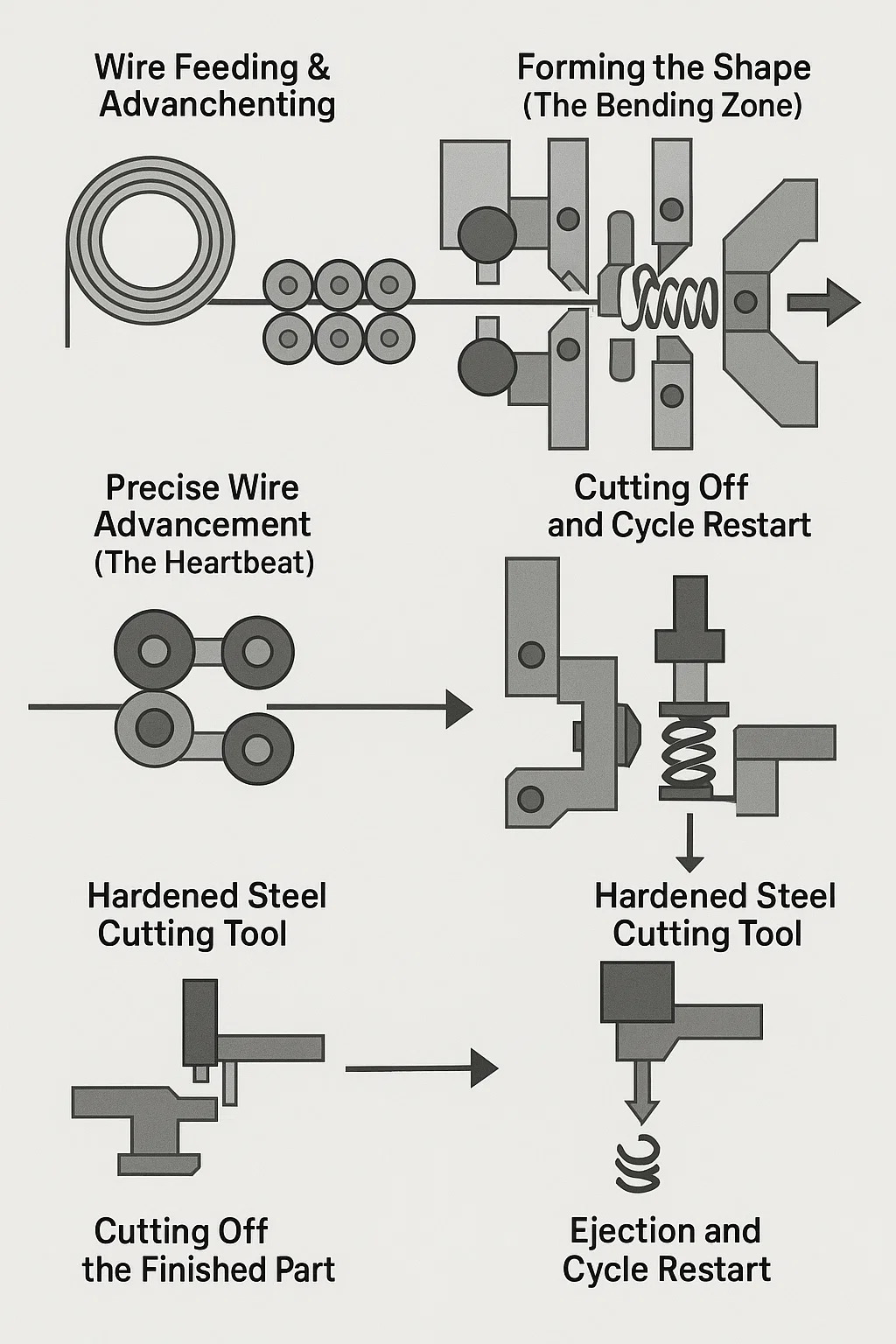

Spring machines transform coiled metal wire into springs or wire forms through a precise sequence of mechanical actions. Here's how they operate:

Coiled wire is mounted on a rotating payoff reel behind the machine.

The wire feeds into a set of straightening rollers (typically 5-10 hardened steel rollers arranged alternately). As the wire passes through, these rollers apply controlled pressure to remove any curves or kinks from the coil memory, producing perfectly straight wire entering the forming area.

The straightened wire passes between a pair of powerful, knurled feed rollers.

A servo motor (in CNC machines) or a cam-driven mechanism (in mechanical machines) rotates these rollers intermittently. Each rotation pushes a precisely calculated length of wire forward into the forming tools. This exact feed length determines critical features like the spring's overall length and coil spacing.

As the wire advances, it moves into the forming area where multiple forming tools (also called tools, fingers, or slides) are positioned.

These tools are mounted on sturdy tool posts around a central arbor (mandrel) or forming pin that defines the inner diameter.

Cams (Mechanical) or Servos (CNC): Dictate the movement sequence:

Mechanical Machines: Rotating cams physically push or pull levers connected to the forming tools via linkages. Each cam profile controls the timing and distance one tool moves inward or outward.

CNC Machines: Individual servo motors directly drive each forming tool independently. A computer program precisely controls the position, speed, and timing of every tool movement.

The Bending Actions: As the wire feeds to the correct position:

One tool might slam sideways to create a bend or offset.

Another tool might rotate sharply to wrap the wire around the arbor, forming a coil.

Tools can press vertically to create loops or hooks at the ends.

A pitch tool might move in synchrony with the feed to control the spacing between coils as they wrap.

Multiple tools act in rapid, coordinated succession to progressively bend the wire into the desired complex shape.

Once the final bend is formed, a hardened steel cutting tool (often a blade or guillotine) is actuated.

It moves swiftly and forcefully against an anvil or stationary blade, shearing the formed spring or wire part cleanly from the remaining wire feed stock.

The timing of the cut is synchronized precisely with the end of the forming cycle.

After cutting, the formed part is either allowed to drop by gravity down a chute or gently pushed out of the forming zone by a retracting tool.

The forming tools simultaneously retract back to their "home" positions.

The feed rollers immediately advance the next precise length of wire.

The cycle repeats continuously at high speed (potentially hundreds of parts per minute).

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details