The core of spring making: bending straight steel wire into the desired loops or shapes while maintaining its elasticity.

Content

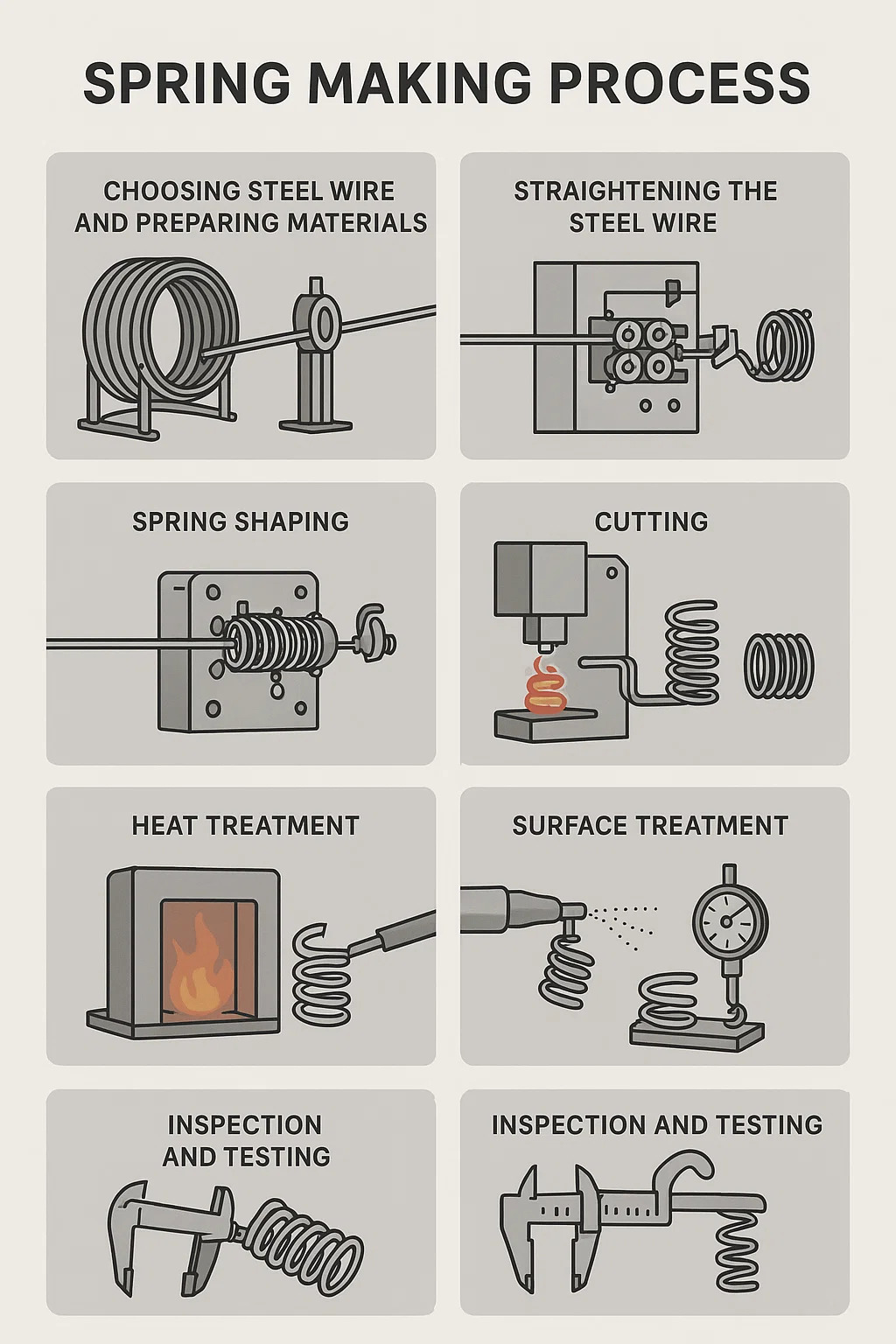

• First, you need to choose the right steel wire. Spring wire comes in different thicknesses (wire diameter) and materials (such as ordinary steel, stainless steel, piano wire, etc.). The choice depends on the force the spring needs to withstand and the environment in which it will be used (e.g., whether it will rust).

• The purchased steel wire is usually coiled into a large roll (coil). Before making the spring, this roll of wire must be placed on a machine (unwinding frame).

• Coiled steel wire is bent and cannot be used directly to make a spring. The machine will pass the wire through a set of straightening rollers (like passing it through several small rollers), pressing it straight.

• This is the most crucial step, accomplished by a specialized spring machine. There are many types of spring machines, but the principle is the same: bending straight steel wire in a pre-set manner.

• Wire Feeding: The machine has two toothed wheels (feeding wheels), which, like a conveyor belt, precisely advance a length of wire each time. This length determines the number of spring coils, the total length, etc.

• Wire Bending: In the machine's working area, there are several movable bending tools (like little fingers or sliders). The machine controls these tools:

• Some tools wind the wire around a mandrel (spindle), forming spirals (the basis of compression/tension springs).

• Some tools push or bend the wire at specific points to create bends, hooks (hooks), or specially shaped ends (end shapes).

• Some tools control the distance between the spiral coils (pitch).

• Old-fashioned machines (cam machines): These rely on specially shaped rotating wheels (cams) inside to push levers, which in turn move the bending tools. Adjusting the machine is cumbersome; changing the spring shape requires changing the cam and spending a lot of time adjusting.

• New-style machines (computerized spring machines/CNC spring machines): This is the mainstream type now. The operator inputs the spring's dimensions (thickness, coil size, number of coils, hook bending method, etc.) onto the machine's computer screen, and the machine's computer (controller) remembers these instructions. Then, multiple small motors (servo motors) within the machine control the wire feed rollers and each bending tool, precisely bending the steel wire into the desired shape according to the program. Want to change to a different type of spring? Simply select the new program, change the tool, and it's done quickly.

• Once the spring shape is formed, the machine's cutter (like a small guillotine) immediately moves, cleanly and neatly cutting the formed spring from the steel wire behind it.

• Freshly bent steel wire has internal stress, making it relatively brittle and lacking elasticity, easily breaking. To make the spring durable and elastic, most springs (especially those with thicker wire or higher requirements) require heat treatment.

• Heating: The spring is placed in a furnace and heated to a specific high temperature (appearing slightly reddish).

• Quenching: The spring is quickly placed in oil or water to cool and harden the steel wire.

• Tempering: Reheat to a slightly lower temperature, hold for a period, and then cool. This step is crucial; it releases stress, giving the spring both hardness and toughness (less prone to breakage), resulting in excellent elasticity. Springs without heat treatment are prone to deformation or breakage.

• Depending on the spring's intended use, various surface treatments may be required:

• Shot Peening/Shot Blasting: Using high-speed small steel balls to blast the spring surface removes rust and burrs, and also strengthens the surface (compressive stress), increasing its lifespan.

• Electroplating/Blackening: Plating the spring surface with zinc, nickel, chromium, etc., or applying a blackening treatment, primarily for rust prevention and improved appearance.

• Coating: Spraying on paint or a plastic layer for rust prevention.

• Finally, the finished spring must be inspected:

• Dimensions: Measure the total length, outer diameter, inner diameter, wire diameter, hook angle, etc., to ensure they meet specifications.

• Elasticity Test: Use a specialized machine to compress or stretch the spring to see how much force is required to compress/stretch it to the specified length (elasticity test), and whether it will break when fully compressed/stretched (fatigue test sampling).

• Surface Inspection: Check for cracks, severe scratches, rust spots, etc.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details