At present, industrial applications are various

CNC spring machines, also known as computer spring machines, which can be divided into computer spring machines, universal spring machines, camless spring machines, extension spring machines, torsion spring machines, snake spring machines, forming machines, etc. special machine. Among them, in industrial applications, compression spring products account for a large proportion, such as cylindrical coil springs, tower springs, conical springs, and convex/concave springs. , the demand is large, and the precision requirement is high. For users, it is very important to understand the working principle of the computer compression spring, so how to solve the working principle of the computer compression spring?

The working principle of the computerized spring press: use one or several pairs of rollers to compress and rotate the steel wire, push the steel wire forward, and form the steel wire through the limit and guide function of the upper and lower ring diameter rods. The steel wire constantly moves forward in the respective chutes of the upper and lower ring diameter rods. By controlling the position of the upper and lower ring diameter rods, the diameter of the spring ring can be controlled. The pitch rod moves perpendicular to the paper surface, and its function is to make the wound steel wire form a thread angle; by controlling and adjusting the position of the pitch rod, the pitch of the spring can be controlled. After the winding of the spring machine is completed, the steel wire is cut off with a knife; when the cutter cuts the steel wire, the mandrel plays a supporting role.

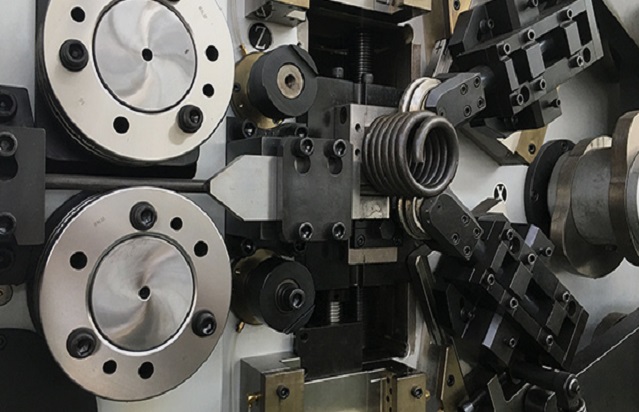

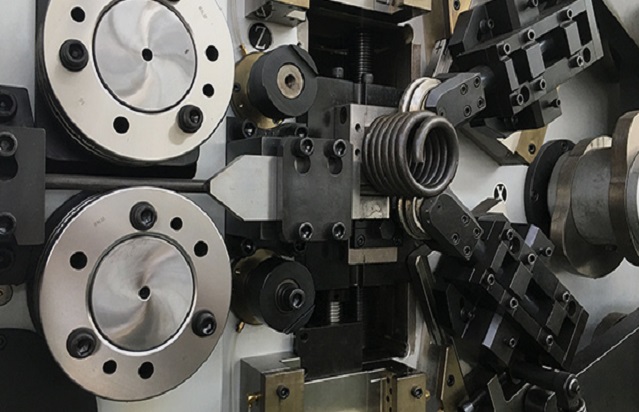

The computerized spring press consists of five structural units: straightening mechanism, feeding mechanism, variable diameter mechanism, pitch control mechanism and cutting mechanism. Each structural unit performs a different task, thereby coordinating the winding and forming processing of the spring product. The computer spring machine continues to develop on the basis of two axes, and then gradually develops into three-axis, four-axis, five-axis, six-axis, eight-axis, and multi-axis computer spring machine products, which have stronger forming functions, higher precision requirements, and higher speed. Faster, more convenient debugging, and more convenient operation.