CNC technology can be used to manufacture springs, and it's currently the mainstream method. Specifically, it works like this:

Content

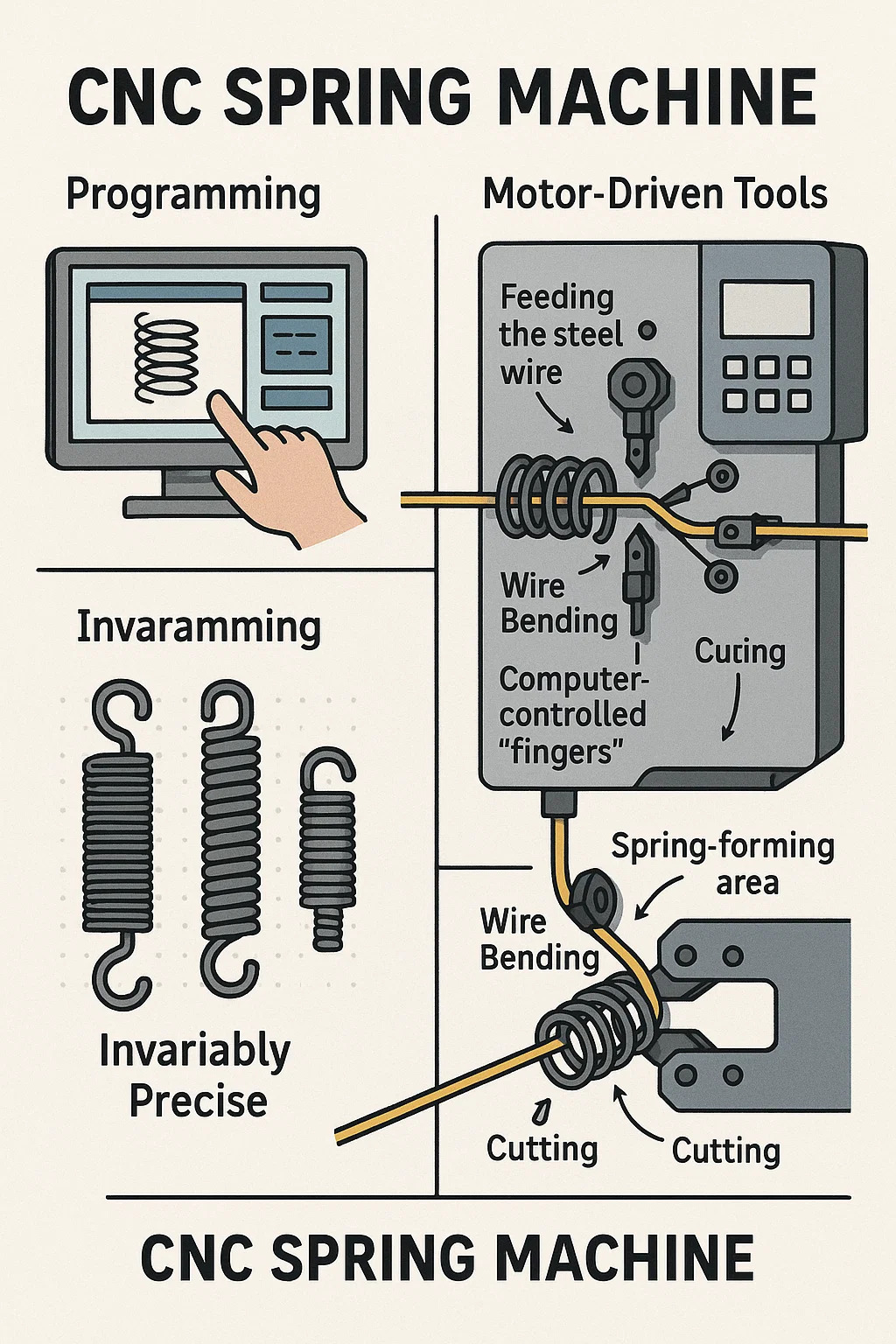

There's a machine specifically designed to manufacture springs called a computer-controlled spring machine (or numerically calibrated spring machine). Its core is using a computer (CNC system) to control the entire spring manufacturing process.

First, the operator "tells" the machine what kind of spring you want on its computer screen: What's the thickness of the steel wire? How big are the spring coils? How many coils are needed in total? How far apart are the coils? Should the ends be bent into hooks or circles? What angle is needed? etc.

The machine's specialized software then translates these requirements into detailed, step-by-step instructions that it can understand (essentially an electronic blueprint for the spring).

Feeding the steel wire: The machine has two toothed rollers, precisely controlled by a motor. It pushes in a set length of steel wire at a time, which determines the spring's length and coil spacing.

Wire Bending: In the spring-forming area, several movable bending tools (imagine several flexible and powerful "fingers") surround the wire, each controlled by its own independent motor.

Computer-Controlled "Fingers": The computer, according to a program, simultaneously commands the motors of these "fingers" to work. Some "fingers" push the wire to bend it at an angle, some rotate it to coil it around the central core, and some move to control the tension between coils. These actions work quickly, precisely, and in coordination to bend the straight wire step by step into the shape of your designed spring.

Cutting: Once the spring shape is complete, another motor-controlled cutter immediately moves, "snip!" cleanly severing the formed spring from the wire behind it.

Make whatever you want: It can create very complex spring and wire shapes, such as springs with many bends, special hooks, or springs with varying coil sizes, which are difficult or even impossible to do on older machines.

Super-fast design changes: Finished making one type of spring and want to make another? Simply access the new program on the computer, quickly change the corresponding "finger" and mandrel, and you can start making the new one immediately. Unlike older machines that require half a day of disassembly and adjustment when changing designs.

Invariably precise: The computer-controlled motor has extremely high precision, ensuring that every spring produced is perfectly sized and of consistently high quality.

Effective for small batches: Even if you only need to make dozens or hundreds of different springs, you don't need to spend a lot of time adjusting the machine, making it especially suitable for sample production or small orders.

Saying "CNC spring" refers to manufacturing springs using a computer-controlled spring machine. It uses computer programming to issue instructions, directing multiple independent motors to drive bending tools and cutters, precisely, quickly, and flexibly bending and cutting a roll of steel wire to obtain the spring you designed. This method is the core of modern spring production because it is fast, accurate, and capable of producing complex shapes.

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK-13200、 TK-7230 TK-13200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK12120 TK-12120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-6160 TK-6160 CNC SPRING ROLLING MACHINE...

See Details

TK-6120 TK-6120 CNC SPRING ROLLING MACHINE...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details