① Improve the high efficiency and precision requirements of

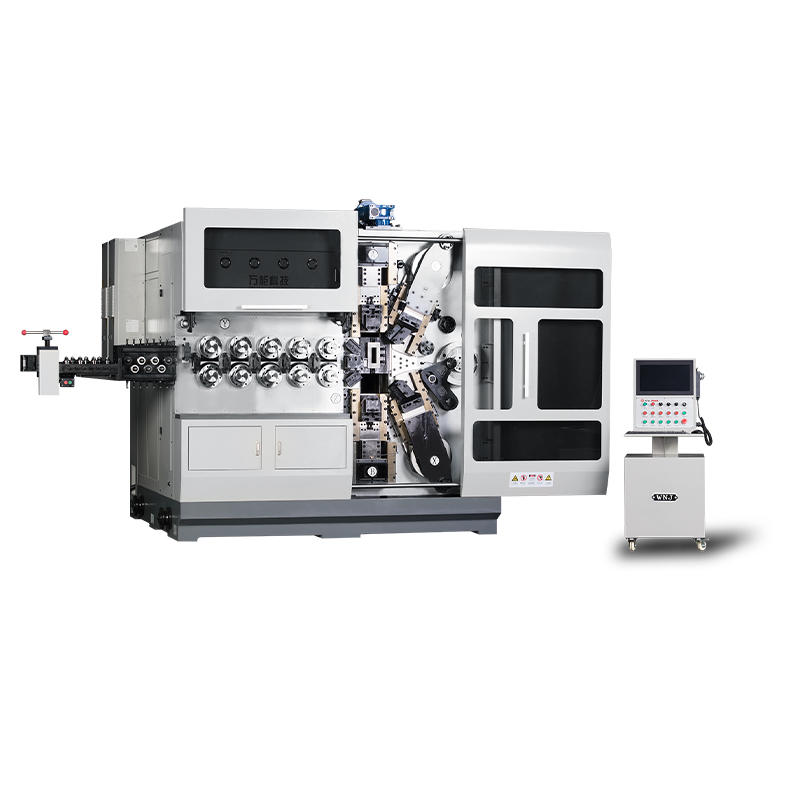

spring machining. The high-efficiency and high-precision requirements of spring machining, in the main application of industrial production, the sales market demand of spring machines is very huge. In addition, the precision requirements of spring machines are getting higher and higher, so it is particularly important to improve the processing efficiency and ensure the precision requirements. With the development and application of compression spring machine technology, the advantages of compression spring machine equipment will gradually be best reflected. Due to the selection of electrical components such as servo system and industrial computer, the reliability of the operation of the compression spring machine is greatly guaranteed. The use of high-precision transmission gears, imported rolling bearings, and prefabricated parts of high-processing machinery fully guarantees the high-precision requirements of the compression spring machine in the whole process of spring machining. In the whole process of spring machining, the use of the compression spring machine reduces the processing cycle of the product and greatly improves the processing efficiency of the spring machine. Therefore, the development of compression spring machine has improved the high efficiency and precision requirements for spring machining, and created more profits for customers or spring machine enterprises.

② Reduce the difficulty factor of machine debugging and actual operation requirements. The high efficiency and precision requirements of spring machining, in recent years, the development of the spring machine industry can be said to be developing rapidly, which has brought great changes to the spring machine manufacturing industry. In particular, the development and application of the camshaftless spring machine, as well as the unique camshaftless and crankless arm design scheme, greatly reduces the difficulty of debugging and the actual operation requirements of the machine. Due to factors such as the increase in labor costs and the difficulty of recruiting technical experts, more and more customers or spring machine companies tend to choose camshaftless spring machines or multi-shaft spring machine equipment. The characteristics of low entry threshold, low practical operation difficulty factor and high work efficiency have gradually become the main product selling points of camshaftless spring machines. More accurate, faster and smarter systems are attracting more and more customers. Recognize and love camshaftless spring machines. Therefore, the development of the compression spring machine reduces the debugging difficulty and actual operation requirements of the machine, and provides a more personalized user experience for many customers.

③ Strengthen and expand production capacity. The processing efficiency and precision of the spring machine are specified. With the continuous development of compression spring machine forming technology, the upgrading of spring machine equipment has been accelerated, and the equipment replacement cycle has been shortened. The introduction of new technologies, the development and application of new products, and the increase in the number of servo rotating axes have greatly expanded the production capacity of the compression spring machine. For example, the spring machine series products on the computer have been gradually upgraded from the basic 2-axis to 3-axis, 4-axis, 5-axis, 6-axis or 8-axis, and the spring machine series products have been upgraded from the basic 3-axis to 4-axis or without cam 5 axes. The shaft spring machine series is upgraded from the basic 10-axis to 11-axis, 12-axis, 13-axis or 14-axis. The number of servo rotary axes is increasing and artificial intelligence is slowly being used. Therefore, the development of the compression spring machine has gradually improved its role in the main application, and gradually expanded its more powerful production capacity.