1) The grinding head spindle is locked due to overheating

The main reason for this phenomenon is impurities mixed in hydraulic oil. For example, dust, iron powder, etc. Impurities in the hydraulic oil will block the small oil holes in the bearing bush, resulting in part of the hydraulic cavity without hydraulic oil, so that the spindle cannot form a symmetrical pressure oil cavity. The main shaft is not in a pure liquid state when it is rotating, and it rubs against the bearing bush to generate heat. After disassembling the spindle of the surface grinder and inspecting the parts, it was found that the roundness of the spindle was not too bad, but the surface finish was poor. The roundness of the inner hole of the bearing bush is not out of tolerance, there are scratches on the surface of the inner hole, and the section of the bearing bush is scratched. The capillary oil hole in the bearing bush is blocked. After polishing the surface of the main shaft and the inner hole of the bearing bush with metallographic sandpaper, it can reach the standard of use.

The difficulty in repairing is how to remove impurities in the 0.5mm capillary oil hole in the bearing bush. The capillary can only establish static pressure balance in the bearing bush when each oil through hole is opened. The bearing bush is assembled in the cast iron bushing, and a special pull hammer is required to separate the bearing bush from the bushing. After the bearing shell is separated, the bearing shell can be cleaned, and each oil through hole can be opened. Finally, clean the oil tank and replace with new hydraulic oil. After all the repair work is completed, the test run can be returned.

2) Poor finish of grinding parts

The radial runout of the main shaft is too bad, which causes the grinding wheel to vibrate greatly during the grinding process, which makes the surface finish of the grinding workpiece poor.

The main reasons for the excessive radial runout of the surface grinder spindle are:

(1) The spindle collides or deforms under force.

(2) The roundness of the inner hole of the support bearing bush of the main shaft is out of tolerance.

The grinding head part of the surface grinder adopts the support mode of the front and rear bearing shells. The static pressure technology is applied to it. Two oil return grooves with a depth of 0.8mm and a width of 4mm are opened at the front end of the bearing shell. The machining and assembly accuracy of the bearing bush will have a serious impact on the quality of the M7140 hydrostatic grinding head. The gap between the bearing bush and the main shaft in the diameter direction is 0.07mm, which can be used for troubleshooting and precision repair according to this data. After the main shaft was disassembled, it was found that the main reason for shaft vibration was that the roundness of the inner hole of the bearing bush was too poor, which caused the static pressure balance to be destroyed, causing the main shaft to produce greater vibration when rotating. To repair the inner hole of the bearing bush and restore the roundness of the inner hole of the bearing bush, grinding can also be used.

First, three grinding rods of different sizes are made of cast iron. The three grinding rods of different sizes are used for rough grinding and fine grinding of the inner hole of the bearing bush. The length of the grinding rod is unified to 600mm according to the size of the bearing bush. And the grinding rod needs to be made into a waist drum shape. Assemble the bearing bush of the main shaft and the steel sleeve uniformly, and pay attention to protecting the oil circuit on the bearing bush surface during assembly. Use the chuck of the lathe to clamp and position the bearing bush and the steel sleeve, and pay attention to the leveling of the bearing bush surface to ensure the verticality of the clamping. When the grinding rod is used for grinding, it is necessary to use the crane to lift the grinding rod up and down, and manually make the grinding rod rotate around the axis of the bearing bush. Grinding is carried out according to the steps of first roughing and then finishing. During the fine grinding, a grinding rod whose outer diameter is 0.015-0.025mm smaller than the inner diameter of the bearing bush is used for dry grinding. During dry grinding, the number of grinding should be controlled. After grinding, the surface finish of the inner hole of the bearing bush can reach

Hydrostatic spindle components are widely used in machine tools, which brings the design and manufacturing of machine tools to a new level, and also brings new problems to the maintenance of machine tools. The repair process of the hydrostatic spindle is more complicated and delicate, and the repair period is long, which easily affects production. Therefore, the usual maintenance work is very important.

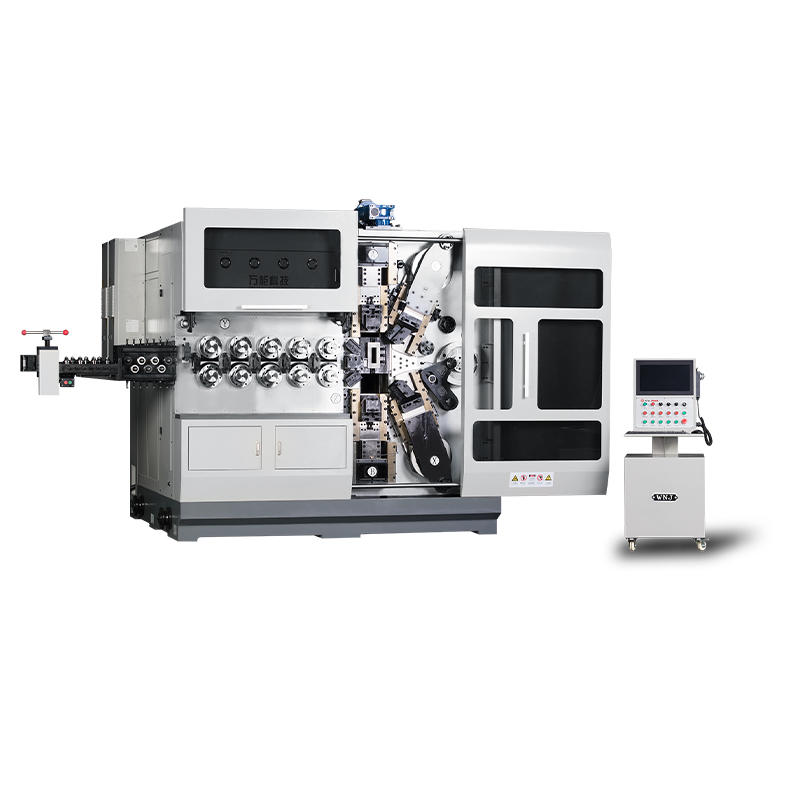

TK8120 TK-8120 12AXES CNC SPRING COILING MACHINE...

See Details

TK-7200、 TK-7230 TK-7200、 TK-7230 12AXES CNC SPRING COILING MACHINE...

See Details

TK790 TK790 6-7AXES CNC SPRING COILING MACHINE ...

See Details

TK-5200 TK-5200 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5160 TK-5160 5AXES CNC SPRING COILING MACHINE...

See Details

TK-5120 TK-5120 5AXES CNC SPRING COILING MACHINE...

See Details

TK-580B、 TK-590 TK-580B、 TK-590 5AXES CNC SPRING COILING MACHINE...

See Details

TK660 TK660 6-7AXES CNC SPRING COILING MACHINE ...

See Details

TK TK 10AXES CNC SPRING SCROLL MACHINE...

See Details

TK-550B TK-550B 5AXES CNC SPRING COILING MACHINE...

See Details